Sugarcane baggasse dryer

Author: Admin View: Post Time: 2016 / 12 / 30

Product Description

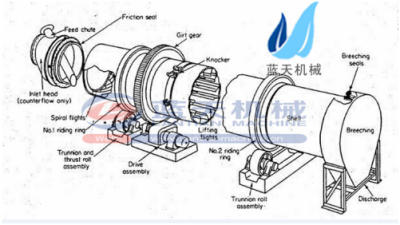

The working principle of Sugarcane baggasse dryer:

The drum of the dryer is a slightly inclined cylindrical rotatable body. The wet material enter into from the upper end and dry material are collected from the lower part of the other side. Hot air enter from the feeder end or the discharge end. And exit from the other end of the upper part. Cylinder allocated with forward copy board make the material in the process of rotating in cylinder are constantly raised and shed and made full contact with the hot air, in order to improve efficiency and make the drying material to move forward. Usually the heating source of dried mateiral is heat hot air, hot flue gas and water vapor.

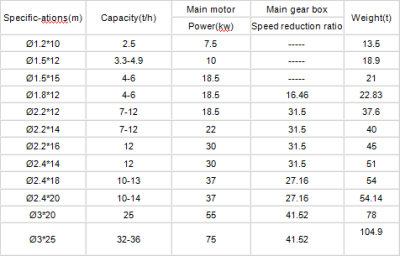

2.Technical Parameters of Sugarcane baggasse dryer:

3.Application of Sugarcane baggasse dryer:

1) Ore: ore, slag ,mineral power, limestone, quartz, fluorite powder, iron ore, metal ore concentrates, metal tailings, etc.

2) Metal: metal powder, iron powder, iron filings, steel scrap, copper filings, etc.

3) Chemical industry: gypsum powder of desulphurization gypsum stir-frying half water model and building gypsum powder, clay, diatomaceous earth, kaolin, bauxite

4) Coal: raw coal, coal slime, coal, coal ash, coal cinder.

5) Sand: sand, quartz sand, molding sand, river sand.

6) Various crystals: light calcium carbonate, activated clay, magnetic powder, graphite, mineral mud, clay, lime slurry, ore slurry, phosphorus slag, aluminum red mud, feldspar powder, fly ash, blue carbon, potassium, sodium, calcium, barium and alkali metal or silicate minerals in the metal.

The process of Sugarcane baggasse dryer

1. Materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator.

2. Materials enter the barrel installed with slope to horizontal line from the higher side, and hot air enters the barrel from the lower side, and then materials and hot air mix together.

3. Materials go to the lower side by gravity when the barrel is rotating.

4. Lifters on the inner side of barrel lift materials up and down in order to make materials and hot air mix completely, which is designed to improve the producing efficiency of rotary dryer.

The advantages of Sugarcane baggasse dryer

(1) large production capacity, continuous operation

(2) has the advantages of simple structure, convenient operation

(3) less failure, low repair cost

(4) wide application range, can also dry granular objects, for those big material also favorableadhesion

(5) the operation elasticity is large, there is a larger range of production allows the output of products, does not affect the quality

Dry sample:

At the scene of bagasse dryer:

Packaging & Shipping

Company Information

Gongyi lantian Mechanical Plant, built in 1980s, is specialized in manufacturing all knids of briquette machines, dryers, brick making machines and auxiliary machines. We have about 30 years' manufacturing experiences and we have spent a lot time for researching, designing and developing our machines. Now we have stood out in this mechanical industries.

We sincerely hope to cooperate with you. And warm welcome to our factory to see the machines working.

Contact Information:

If you want to visit our Chinese factory, please note our city name, Zhengzhou city.

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station.

If you are interested in our products , please send inquiry to our email:Alisa@lantianmachine.com

HOME

HOME PRODUCTS

PRODUCTS CONTACTS

CONTACTS