Spontaneous carbonization furnace

Author: Admin View: Post Time: 2016 / 12 / 23

Product Description

The finished Spontaneous carbonization furnace product:

1.Production description of Spontaneous carbonization furnace :

Coconut shell carbonization is using dry distillation carbonization principle, through hypoxia heating decomposition to generate combustible gas, tar oil and charcoal. It has features of unique structure, large effective volume, advanced carbonization technology, short cycle, high yield, good environmental protection, long service life, etc. Also we can customize high, medium and low temperature carbonization stove according to customers special requirement.

The body is made of resistant high temperature steel plate, not easy to deformation and oxidation, also good insulation properties.

2.Raw materia of Spontaneous carbonization furnace:

1) Agricultural waste: straw, stalk, corn cob, peanut shell, grass, etc.

2) Forest waste: wood log, branches, leaves, sawdust, etc.

3) Coconut shell, kernel, sunflower shell, nuts, etc.

4) Bamboo.

Note:Recently years, our factory research and develop coal carbonization technique, it can carbonize ordinary coal, lignite coal, and other kinds coal into smokeless coal, which value is higher than high quality charcoal.

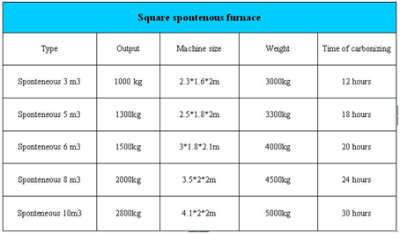

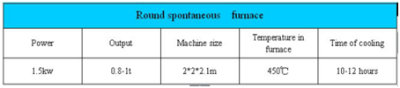

3.Square shape and round shape of Spontaneous carbonization furnace as follows:

Square self ignite furnace:

Round self ignite furnace:

4.The working principle of Spontaneous carbonization furnace :

(1). Drying stage: First, we should set fire on wood, tree branches, wood briquettes, etc.(which we have laid in the carbonization furnace) through four holes which locate furnace's bottom. Then close the holes. And close the upper holes till the thermometer (which loactes on the surface of thr furnace) reaches 100°C. At this stage, the temperature in the furnace will reach about 100-160°C,and all the water content will be evaporated.

(2). Initial phase of carbonization: At this stage, the temperature in the furnace will reach 160-280°C, wood, tree branches, wood briquettes, etc. will be decomposed into carbon dioxide, carbon monoxide, etc.

(3). Carbonization stage: At this stage, the temperature will reach 280-450°C, wood, tree branches, wood briquettes,etc. will be decomposed rapidly and finally carbonized into charcoal.

(4). Carbonization time: 34 hours (Carbonize briquette in furnace about 14 hours,then cool them about 20 hours in carbonization furnace)

2). Bamboo:

3). Wood log:

Factory

1. Established in 1980s, our company covers an area of 100,000 square meters which includes 66,000 square meters of workshops. We have the most advanced technology, most strict process, from material purchase to the finished products, all strictly according to the national quality inspections standards.It mainly specilize in charcoal making machine, sawdust briquette machine,briquette machine,powder making machine,extruder machine, BBQ machine,honeycomb briquette machine,carbonization furnace,heat pump dryer and so on.

2. As manufactures, we have more than 30 years of experience, our products all achieved patent certificates, and our company has many times achieved the title of honer: " Observe Contract and Keep Promise" " Quality Trustworthy Product" "Good After-sales Service Reputation", etc.

Contact

If you want to visit our Chinese factory, please note our city name, Zhengzhou city.

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station.

If you are interested in our products , please send inquiry to our email:Alisa@lantianmachine.com

HOME

HOME PRODUCTS

PRODUCTS CONTACTS

CONTACTS