Coconut shell carbonization furnace

Author: Admin View: Post Time: 2016 / 12 / 22

Product Description

The final Coconut shell carbonization furnace production line:

1.Introduction of Coconut shell carbonization furnace:

The airflow charcoal manufacturing oven is our new invent, which is also combined type. The charcoal can be hoisted outside, in this way the cooling time can be reduced much, thus, the productive efficiency increases a lot. It is the ideal choice for mass production of charcoal.

This type of furnace adopts the structure of unique air storage chamber, to fully reuse the smoke produced during the process of carbonization. And 60% of the redundant smoke can be used in drying and carbonizing, saving much fuel during the whole process, and increasing the enterprise revenue.

Raw materials of Coconut shell carbonization furnace:

1. Tree branches whose diameter is more than 30mm.

2. Some nut shells, such coconut shell, walnut shell, etc.

3. Biomass briquettes made from sawdust, small agriculture wastes.

Square type:

Round type:

2.The main parts of Coconut shell carbonization furnace:

(1) Outer stove:

Includes heating room (for heating the inner stove), furnace body and heat-keeping layer (it is made of the heat insulating material)

(2) Inner stove:

Consist of the stove tank body and the sealed top cap. Both of them are made of the heat resistance thermal steel, three inner stove can be stacked together for saving space and shipping cost.

(3) Smoking recycle tube.

During the process of carbonizing, there will be some smoke.( can be burning) the smoke can be collected and returned to the furnace.

(4) Purification tank.

This system is consisting of purification tank and the exhaust-heated cycle pipe.

(5) Hoisting equipment.

It include the steel hoisting frame and the E-hoist .And it is easy for loading and unloading the stove.

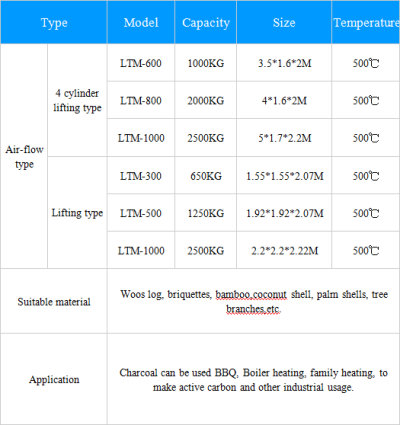

3.Parameter of Coconut shell carbonization furnace:

PS 1: Load 2.5tons machine-made briquettes, 8hours will get 1000kg machine-made charcoal.

PS 2: Load 2tons natural wood, 8-10hours will get 600kg-800kg natural charcoal.

PS 3: Normally it takes 8-10hours. Maybe longger for fresh wood to remove moisture.

PS 4: Heat value: 5500-7000KCAL / KG

PS 5: Raw material: Machine-made charcoal, wood ,coconut shell, wood briquette, bamboo, almond shell, plam shell,

PS 6: Operation: one people one shift ( one day two shift)

PS 7: Energy consumption 20-30kg firewood or 15kg liquid gas.

4.How to produce charcoal? It divides into three processes:

(1). Heat.

After sealing work, use wooden wastes or gas to heat furnace. Primarily, 10 minutes big fire to burn, when the temperature reaches 90 degrees centigrade, turn to use slow fire to heat. It takes 80-120minutes for this process to reduce water vapor from your materials.

(2). Pyrolyse.

Keep heating, when the temperature reaches 180-235 degrees centigrade for 3-5hours, it will produce gas from this process. Reuse this gas as fuel to heat. The whole process is about 8hours. When the temperature reach highest and it reduces, the dry distillation process will finished.

(3). Cooling.

Hang the Inner pot outside, and seal the pipes of cover. Let it cool naturally. Cooling time is longer, the quality of charcoal is good. When the temperature lowers than 50 degree, you can take charcoal out. Otherwise, the charcoal will burn again when met oxygen of air.

5.Gas purifier of Coconut shell carbonization furnace:

It is used to eliminate the smoke produced by the wood charcoal carbonization stove, and also it can turn the smoke and some other soluble organic maters into fuel, or some other energy, it is really an environment protect and energy

Packaging & Shipping

Factory

1. Established in 1980s, our company covers an area of 100,000 square meters which includes 66,000 square meters of workshops. We have the most advanced technology, most strict process, from material purchase to the finished products, all strictly according to the national quality inspections standards.It mainly specilize in charcoal making machine, sawdust briquette machine,briquette machine,powder making machine,extruder machine, BBQ machine,honeycomb briquette machine,carbonization furnace,heat pump dryer and so on.

2. As manufactures, we have more than 30 years of experience, our products all achieved patent certificates, and our company has many times achieved the title of honer: " Observe Contract and Keep Promise" " Quality Trustworthy Product" "Good After-sales Service Reputation", etc.

Contact

If you want to visit our Chinese factory, please note our city name, Zhengzhou city.

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station.

If you are interested in our products , please send inquiry to our email:Alisa@lantianmachine.com

HOME

HOME PRODUCTS

PRODUCTS CONTACTS

CONTACTS